Pumps

- Centrifugal single stage

- Centrifugal multi stage

- Self priming

- Peripheral impeller

- Positive displacement

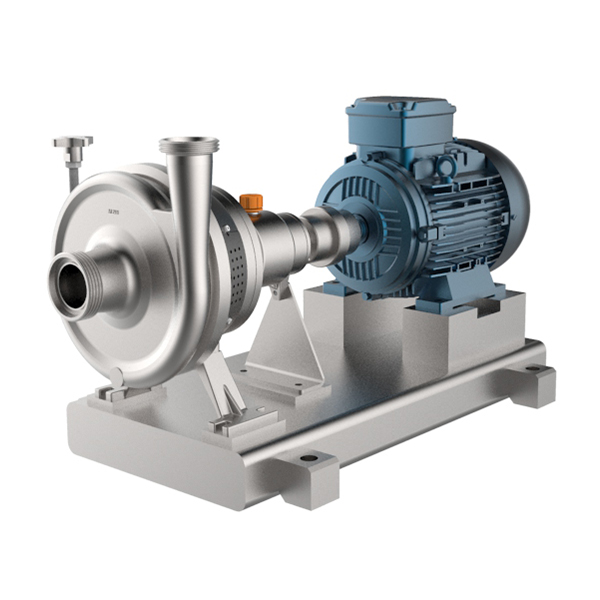

Centrifugal single stage

Single-stage centrifugal pumps are listed in two ranges :

1. HYGIENIC

CS, CSA, CSD, CSK & CR are equipped with its own bearing (IEC independent motorization) and pump body is cast (not in pressed polished plate). Reliability, Robustness, High efficiency, Low NPSH.

CN, CL & CLC, are of conventional configuration.

Standardised mechanical seals EN 12756, ISO 3069 for all CSF pumps.

MKP-Bio, With REVERSE magnetic drive, 100% hermetic, drainable. EHEDG, 3A, FDA certified.

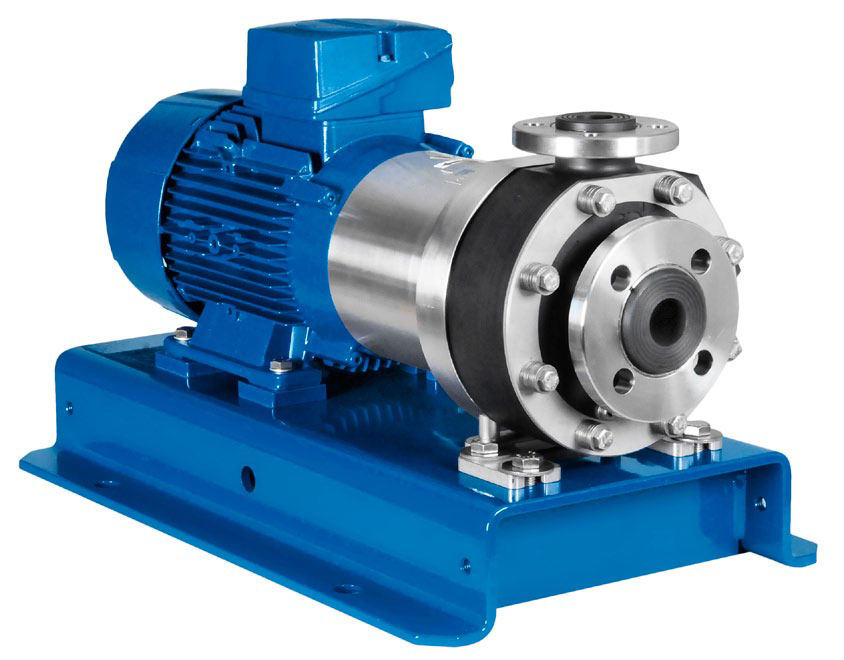

2. CHEMICAL :

MKP, MKP-HT, MKTP : With REVERSE magnetic drive. Can accept up to 30% of particles smaller than 1 mm. Stainless steel 316L, 304L, Uranus B6, Hastelloy, Titanium, Nickel.

MKPL & MSKP : With magnetic coupling. PFA coated (up to 200°C) or solid PTFE.

EB & ET : Double mechanical seal for charged liquids. PFA or Ceramic coated (corrosive and abrasive liquids).

CHEMICAL

Centrifugal multi stage

The multi stage pumps CSM & CV are equipped with its own bearing (IEC independent motorization) and pump body is cast (not in pressed polished plate).

Mechanical seals are standardised to EN 12756, ISO 3069.

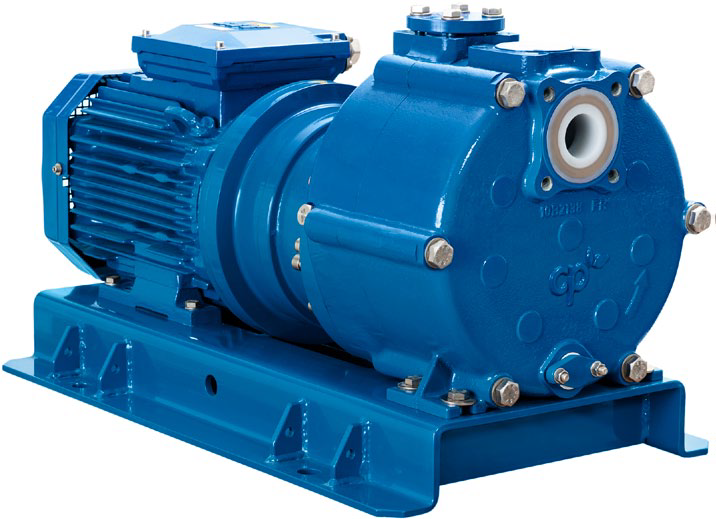

Self priming

Two ranges:

1. Liquid ring :

HYGIENIC

- A (pump body is cast. Vertical inlet),

- AS (The pump body is cast and is equipped with its own bearing. Horizontal inlet),

- ASH in EHEDG and 3A version (The pump body is cast and is equipped with its own bearing. Vertical inlet)

CHEMICAL

- MSKS : Solid PTFE Magnetic Drive

2. Centrifugal :

HYGIENIC

- CNH with the possibility to drain the pump at a single point (UNIQUE).

CHEMICAL

- MKP-S (REVERSE Magnetic Drive) ;

- MKPL-S (PFA Lined – Magnetic Drive)

Standard mechanical seals EN 12756, ISO 3069 for hygienic pumps.

HYGIENIC

CHEMICAL

Peripheral impeller

Peripheral pumps have been developed for applications with low flow rates and high heads as well as for pilot installations.

Two range :

HYGIENIC : The CSF CP pump with standard mechanical seals EN 12756, ISO 3069.

CHEMICALS : The MKPP and MSKPP pumps with magnetic drive.

Positive displacement

A wide range of positive displacement pumps are available with CSF and OMAC :

- Lobe Pumps (OMAC) all possible configurations and materials. From the industrial version to the Super Clean (unique design on the market).

- Twin Screw Pumps : high-tech quality/hygiene design, wide viscosity range, delicate products, which may contain particles and air.

- Progressive Cavity Pumps : very wide range of materials and configurations to meet the majority of applications.

- Sinusoidal Pumps : the ideal pump for products sensitive to shear and foaming, which may contain delicate piece.

- Vertical Pneumatic Piston Pumps : simple and efficient design with good suction power. Much used for emptying drums/barrels, mobile tanks and ATEX applications.

Mechanical seals standardised to EN 12756, ISO 3069.

Twin Screw

Lobe

B/BB/BA (Ruggedness)

- Two double roller bearings/shaft ;

- 1050 lit/100 rpm – 20 bar;

- Industrial or hygienic version.

- Available options :

Rectangular inlet; Double jacket; Aseptic; - By-pass; Titanium, Hastelloy, Monel;

- All types of lobes and seals ;

- Special configurations on request

C - Easy Maintenance/High Quality

- 600 L/100 rpm – 17 bar ;

- Body and fittings machined in one piece

- (no welding) ;

- Developed for easy maintenance and

- hygienic design.

- Options:

Body in stainless steel 316 (1.4435) ;

Bearing housing in stainless steel 304 ;

Special configurations on request.

BF/F + Super Clean version - UNIQUE

- 155 lit/100 rpm – 20 bar; Fe < 3% ;

- Body and fittings machined in one

part (no welding) ; - Stainless steel bearing housing;

- SC (Super Clean) version: rotors and

- shafts are also machined in one piece

- (no seals or cavity for rotor mounting) ;

- Special configurations on request.

Progressive Cavity

MA (Food version)

- 200m³/h – 24 bar ;

- Monobloc version or with bearing

- (double bearing & flexible coupling).

- Options :

Crushing blades at pump outlet ;

Mobile trolley;

Control cabinet ;

By-pass valve;

dry-running and temperature protection; - Special configurations on request.

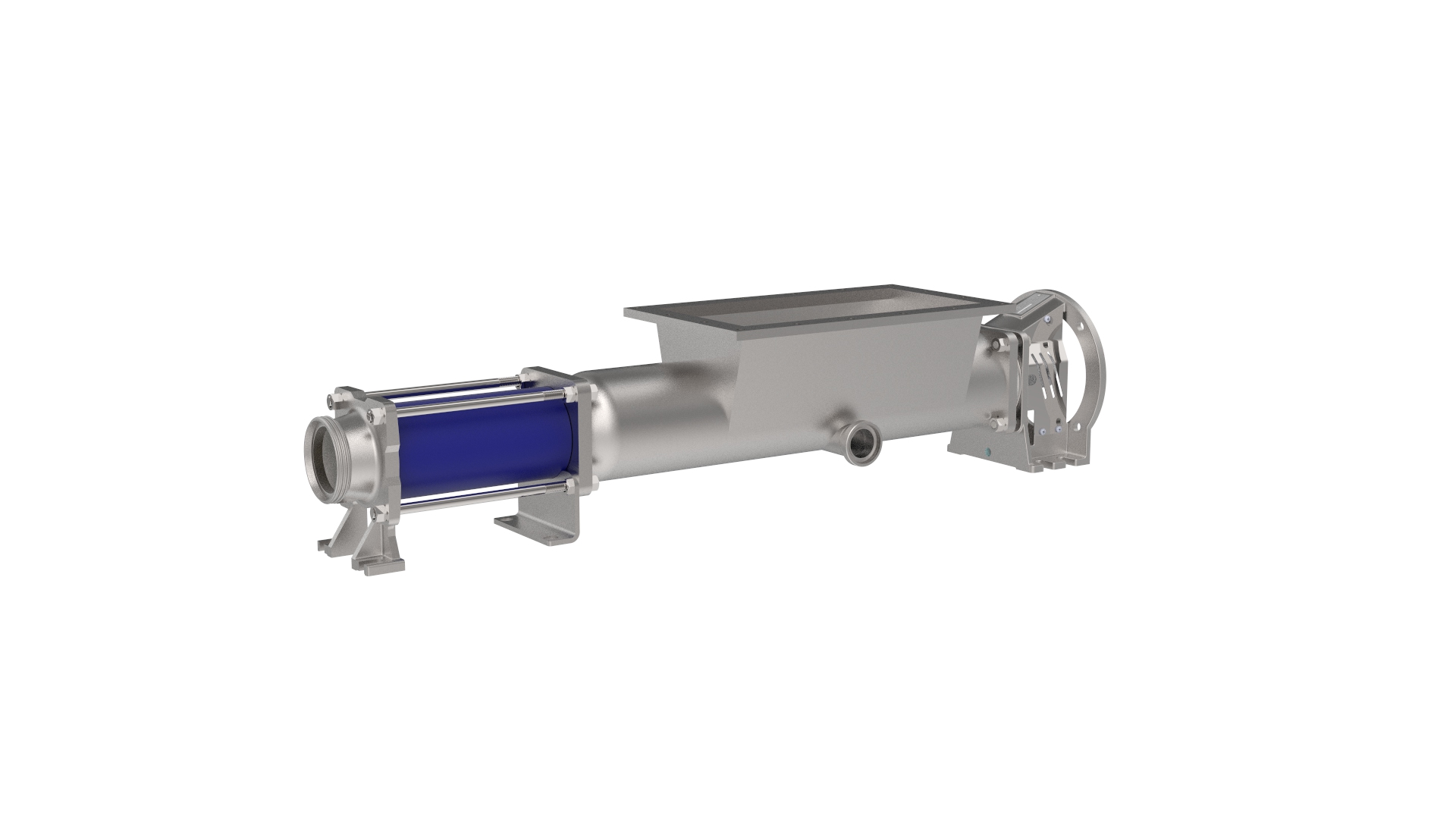

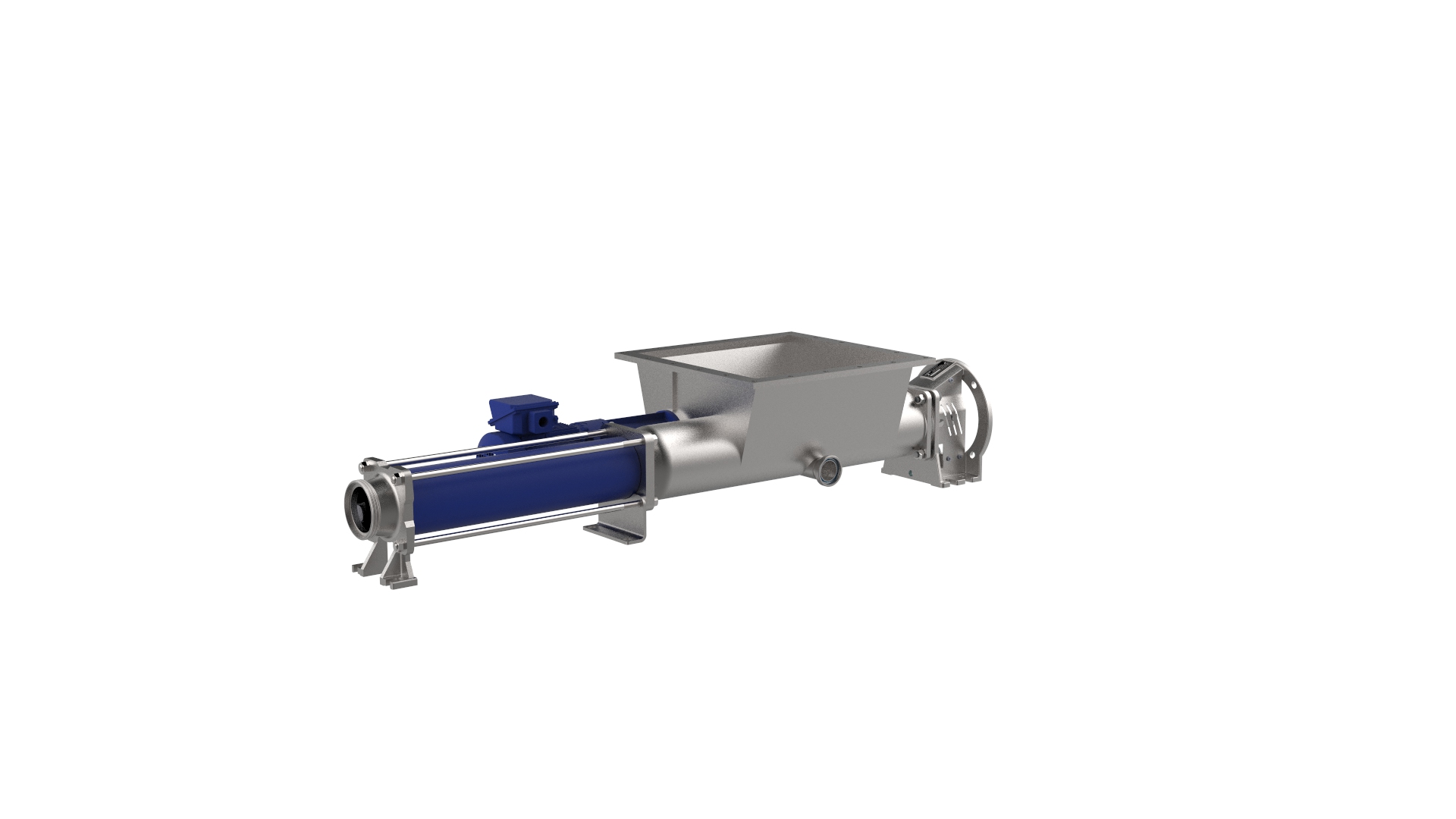

MC2 / MC2R

Features an hoper and twoo pre-feeding screws (MC2), with a blade feeder (MC2R) ;

Monobloc version or with bearing.

Options :

Crushing blades at pump outlet ;

Mobile trolley;

Control cabinet;

By-pass valve;

Dry running and temperature protection.

MC (with hopper and a pre-feeding screw)

- Features a hopper and a pre-feeding screw ;

- Monobloc version or with bearing

- (double bearing & flexible coupling).

- Options :

Crushing blades at pump outlet ;

Mobile trolley;

Control cabinet ;

By-pass valve;

Dry-running and temperature protection; - Special configurations on request.

MAV (vertical food)

- 20 m³/h – 12 bar ;

- Ideal for product discharge delicate in barrels or mobile containers.

- Options :

Control cabinet ;

Dry-running and temperature protection; - Special configurations on request.

MCR (hopper, pre-feeding screw, vane crusher)

- Features a hopper, a pre-feeding

- screw and a vane crusher ;

- Monobloc version or with bearing

- (double bearing & flexible coupling).

- Options :

Crushing blades at pump outlet ;

Mobile trolley; Control cabinet ;

By-pass valve;

Dry-running and temperature protection; - Special configurations on request.

MI (Industrial Version)

- 200m³/h – 24 bar ;

- Robust construction and flanged connections ;

- Monobloc version or with bearing

- (double bearing & flexible coupling).

- Optionals :

Mobile trolley ;

Control cabinet ;

By-pass valve;

Dry-running and temperature protection; - Special configurations on request.